Different Types of Blower Impellers and Their Applications

Blower impellers vary significantly in design and function. Choosing the right type is crucial to optimising performance in industrial systems. This article explores the main types of blower impellers, their working principles, and best-fit applications.

In this article:

Overview of impeller types: radial, axial, and mixed-flow

Understanding the core distinctions between impeller types is essential when designing or selecting industrial air movement systems.

Radial impellers

These impellers discharge air at a 90° angle from the intake direction. Known for high-pressure, low-volume performance, radial impellers are robust and ideal for applications involving particulate-laden or high-temperature air.

Key benefits:

-

High static pressure

-

Efficient in harsh environments

-

Compact construction

Axial impellers

Axial flow impellers push air parallel to the shaft. They are typically used in systems requiring high flow rates with low pressure, such as ventilation or cooling.

Key benefits:

-

High volume airflow

-

Simple mechanical design

-

Energy-efficient at lower pressures

Mixed-flow impellers

Combining characteristics of both radial and axial types, mixed-flow impellers offer moderate pressure and flow rate. These are suited for more balanced industrial needs.

Key benefits:

-

Versatile performance

-

Improved energy efficiency

-

Lower noise levels

Looking for the right impeller-driven fan for your application?

Explore CBI's full range of centrifugal and axial fans engineered for maximum efficiency and durability. Contact our technical team for personalised advice.

Contact us

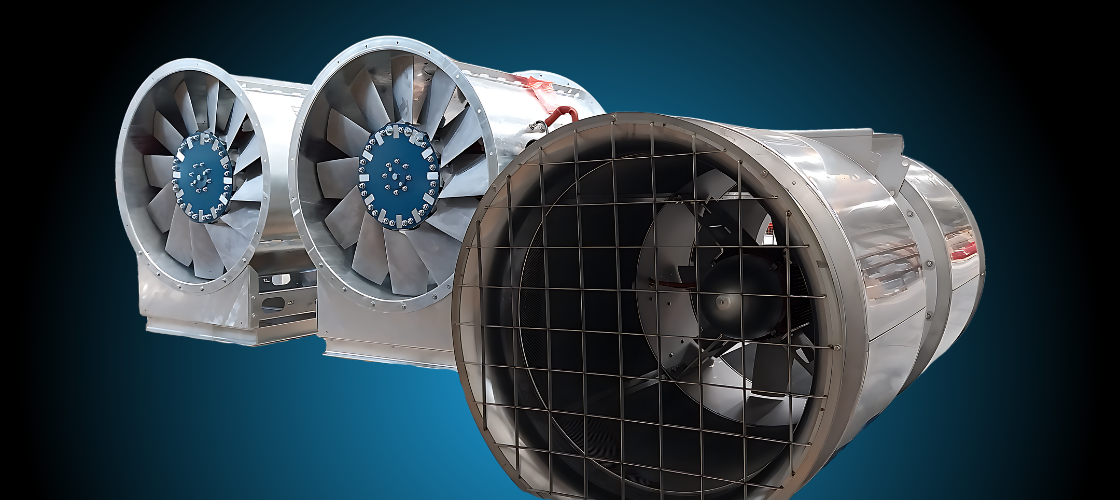

CBI's range of fans with various impellers

CBI offers a comprehensive range of industrial centrifugal fans, each series tailored with specific impeller designs to optimise airflow dynamics and efficiency across applications.

Series CH

Equipped with backwardly inclined curved and backwardly inclined flat blade or airfoil blade, this series is ideal for clean-air applications that demand medium-to-high pressure.

Available in 19 sizes with impeller diameters up to 2.450 mm.

-

Pressure (max): 7.000 Pa

-

Flow rate (max): 460.000 m³/h

-

Blades: backward inclined airfoil or flat balde

-

Directly coupled or belt-driven

-

Handles clean or dusty air

-

Compliant with ErP regulations

Related impeller types:

ChA impeller

-

Reverse inclined airfoil blade.

-

Clean air

-

The shape of the bade allows to reach efficiencies up to 89% with a consequent very low noise level.

ChC impeller

-

Backward inclined flat blade.

-

Air with limited quantity of dust

-

The shape of the blade allows to reach yields up to 80%.

ChB impeller

-

Backward inclined flat blade.

-

Dusty air

-

The shape of the blade allows to reach yields up to 80%.

Series M

The system is designed to withstand temperatures up to 300°C, ensuring robust performance even in harsh environments.

Available in 14 sizes with impeller diameters up to 2.240 mm.

-

Pressure (max): 10.000 Pa

-

Flow rate (max): 340.000 m³/h

-

Static parts: (casing, base supports, motor) are made from robust steel sheet metal, welded and reinforced with ribs and profiles

-

Blades: Flat blades, welded to the appropriately shaped front cone and the rear disc.

-

Additional equipment: The fan is equipped with a small fan for heat dissipation

Series K

This series features adjustable pitch centrifugal impellers, offering flexibility in performance to match varied operational needs.

Available in 18 sizes with impeller diameters up to 2.200 mm.

-

Pressure (max): 9.000 Pa

-

Flow rate (max): 350.000 m³/h

-

Blades: backward inclined

-

Direct or belt-driven executions

-

Processing clean or dusty air

-

In conformity with ERP standard

Related impeller types:

KB Impeller

This type of impeller has an excellent efficiency and is particularly suitable for conveying clean air, fumes, and gases or those containing low concentrations of dust. The KB impeller has 11 backward inclined blades welded to an aerodynamic cone and to the rear disc.

KR Impeller

This type of impeller is used to convey air or gases containing dry granular materials, powders and other materials such as shavings, sawdust, etc. The KR impeller has 8 radial blades welded to an aerodynamic profile cone and to the rear disc.

KF Impeller

This impeller is particularly designed for the transport of materials with strong adherence, heavy or abrasive or filamentary. The KF impeller has 6 radial blades welded to the rear disc and to a special hub.

Discover our full range of centrifugal and axial fans, each complemented with specific type of impeller.

Operational principles of each impeller design

The performance of a blower depends greatly on how the impeller interacts with the air.

-

Radial impellers create centrifugal force, accelerating air radially outward, generating high pressure.

-

Axial impellers rely on lifting air using blade aerodynamics, functioning like a propeller.

-

Mixed-flow impellers combine the centrifugal and propeller effects, achieving balanced pressure and flow characteristics.

Each type uses a unique approach to managing air velocity and pressure, which must align with the operational environment and expected performance.

Selecting the right impeller for your needs

Each industrial environment presents unique challenges. By understanding the types of blower impeller available—radial, axial, and mixed-flow—you can better align your equipment with performance goals.

CBI’s extensive fan range, detailed in the Product Portfolio, demonstrates how tailored impeller designs can enhance operational functionality. Whether you need high pressure, high volume, or a balance of both, choosing the right impeller type is essential for energy efficiency, durability, and system success.

Need support selecting the optimal impeller for your industrial setup?

Our experts are ready to help. Request a consultation or download the full product catalogue for detailed specs and sizing.

Contact us