Axial fan rotation and air flow direction

Axial fans are widely used in industrial ventilation systems due to their capability to move large volumes of air at low pressure. Understanding how the fan's rotation influences the resulting air flow direction is essential for optimal performance.

What is axial fan rotation and air flow direction?

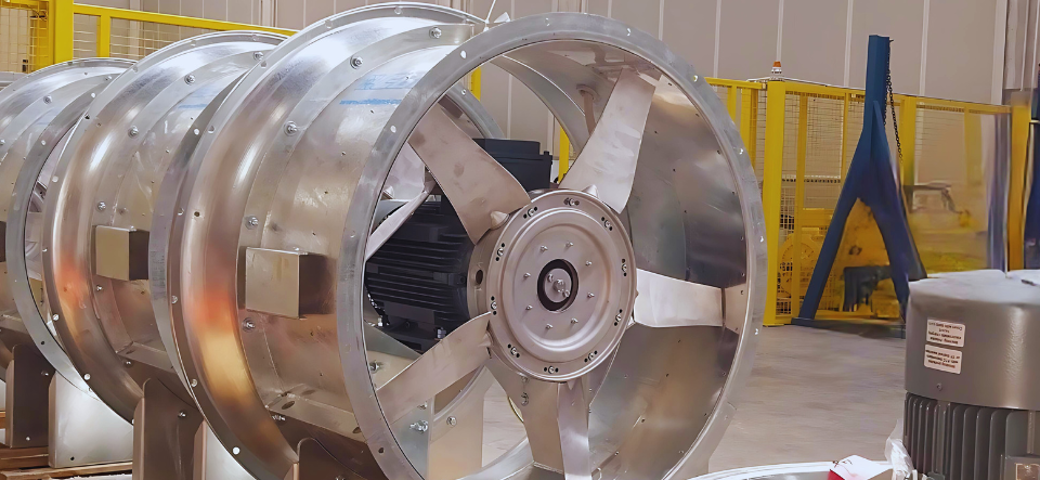

An axial fan moves air parallel to its shaft. As the blades spin, they draw air in and push it along the same axis. The blade rotation — either clockwise (CW) or counterclockwise (CCW) — determines the direction in which the air flow leaves the fan. Since air flow direction depends directly on this rotational movement, selecting the correct configuration is crucial to guarantee the fan operates as intended within a system.

The shape and inclination of the blades are specifically designed to channel air flow, making rotation a key functional parameter to define clearly during installation.

How does axial fan rotation affect air flow direction?

When observed from the motor side, a clockwise rotation typically pushes the air in one direction, while a counterclockwise rotation reverses the air flow. This distinction is significant in installations requiring precise airflow management to avoid counterflows, pressure imbalances or inefficiencies.

In systems with multiple fans or complex ducting, even slight deviations from the intended axial fan air flow direction can compromise overall effectiveness. Ensuring correct alignment of rotation and air flow enhances system stability, safety, and energy efficiency.

Choosing the correct rotation for your system

Selecting the appropriate rotation direction involves evaluating various factors, including:

-

the intended path of the airflow within the system;

-

how the fan interacts with other ventilation components;

-

installation constraints and the physical layout;

-

specific performance or regulatory requirements.

Picking the wrong axial fan rotation direction can reduce performance or cause operational issues, while correct specification ensures optimal air flow, efficient energy use and long-term reliability.

CBI Group’s axial fans: tailored solutions for optimal air flow

CBI Group produces industrial axial fans engineered to meet precise performance requirements. Our product range includes series such as GAT, GAV, GAX, EFA, and AXL, offering varying capacities and pressure handling suitable for diverse industrial needs. These fans feature mono-directional or reversible airfoil blades, modular designs, and can operate under demanding conditions, with some models able to withstand temperatures up to 400°C.

By leveraging advanced automated design systems and custom engineering, CBI Group ensures rapid, error-free development of tailored ventilation solutions. Complemented by comprehensive service, including installation, commissioning, maintenance, revamping, testing and diagnostics, CBI Group delivers reliable axial ventilation built for long-lasting, and safe operation.