Centrifugal fan direction: understanding fan rotation and performance

Centrifugal fans are essential components in many industrial applications, primarily used to move air or other gases through a system. One critical factor that determines their efficiency and effectiveness is the direction of rotation. Understanding centrifugal fan direction is key to ensuring the fan's optimal performance.

What is centrifugal fan rotation?

Centrifugal fans operate by drawing air in through the inlet and expelling it at a 90-degree angle through the outlet. The airflow pattern is determined by the direction of impeller rotation, which can be:

-

Clockwise (CW)

-

Counterclockwise (CCW)

Rotation is identified when viewing the fan from the motor side. Selecting the correct direction is crucial to ensure the fan performs as intended by its design.

How does centrifugal fan rotation direction affect performance?

The centrifugal fan rotation direction significantly impacts:

-

Airflow

-

Generated pressure

-

Energy efficiency

Incorrect rotation results in:

-

Substantial airflow reduction

-

Increased energy consumption

-

Mechanical stress on the impeller and housing

In addition, an incorrect direction may cause imbalances in the duct system, leading to system-wide inefficiencies and potential failures.

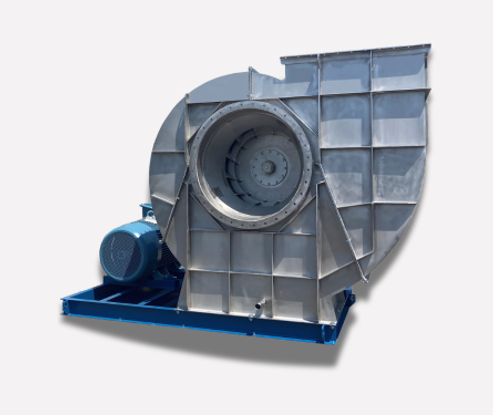

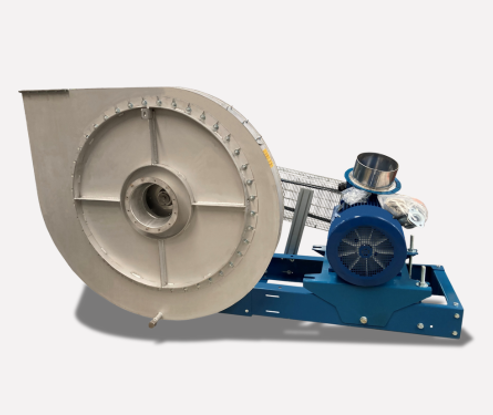

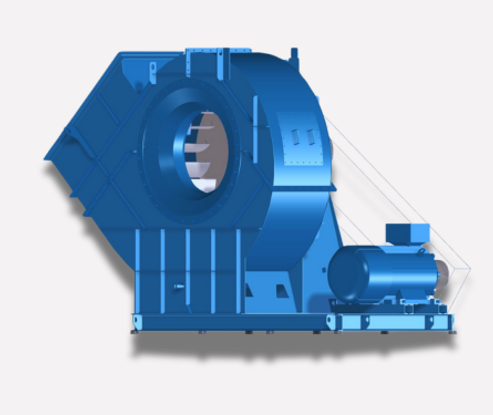

CBI Group’s centrifugal fans: accurate rotation for reliable performance

Based in Monza and operating since 1963, CBI Group is a leader in industrial ventilation. Our centrifugal fans are engineered with precision to deliver optimal performance, even in demanding environments.

CBI manufactures several lines of industrial fans, including:

-

Industrial Centrifugal Fans → Explore the product range

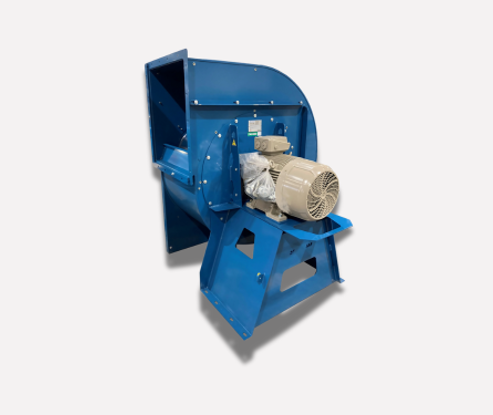

Ch series

Versatility, robustness, and reliability define these fans, making them suitable for a wide range of standard and special industrial applications.

Read all

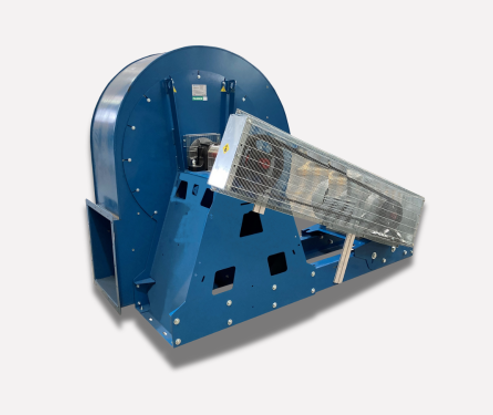

ChT series

The ChT series is a double-inlet fan designed for air-conditioning and ventilation applications, providing a wide range of flow and pressure performances thanks to its high level of standardization.

Read all

K series

The K series is designed for conveying air, dusty gases, granular materials and long fibres, ensuring high versatility and efficiency through its optimized scroll housing and three available impeller configurations.

Read all

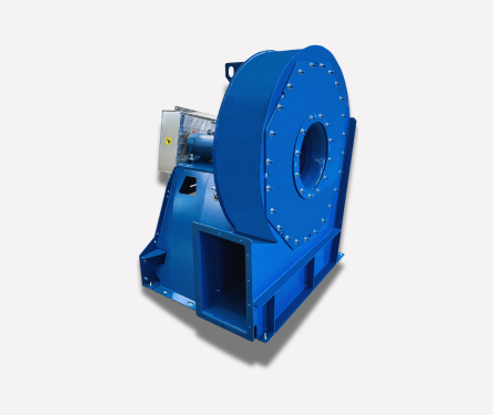

CB series

The CB series includes direct-driven centrifugal fans with either backward flat-blade impellers (CBB) or backward-curved impellers for higher efficiency (CBS).

Read all

N series

The N series consists of direct-driven centrifugal fans designed for versatility and reliability in industrial ventilation systems with low airflow and moderate pressure.

Read all

Z series

The backward flat-blade fan delivers high efficiency and versatility, with configurable direct or transmission drives, multiple material options, surface treatments, and robust design for operation up to 300°C.

Read all

EVO series

The backward flat-blade fan ensures optimal efficiency and reliable direct-drive operation, engineered for robust performance in temperatures up to 400°C.

Read all

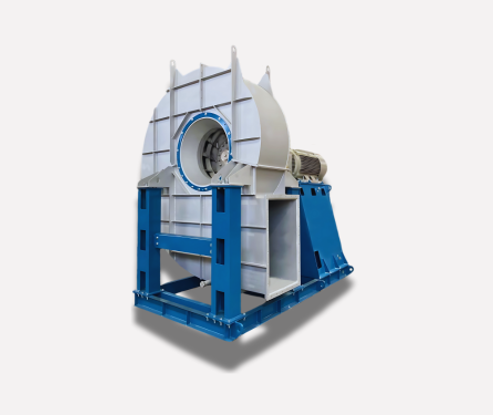

S series

The S/M/X fans are designed for heavy-duty applications, available with direct or belt-driven drives, with 8-blade impellers for the S series, 10 for the M series, and 12 for the X series.

Read all

M series

The S/M/X fans are designed for heavy-duty applications, available with direct or belt-driven drives, with 8-blade impellers for the S series, 10 for the M series, and 12 for the X series.

Read all

X series

The S/M/X fans are designed for heavy-duty applications, available with direct or belt-driven drives, with 8-blade impellers for the S series, 10 for the M series, and 12 for the X series.

Read all

H series

The backward-curved or radial blade fan, delivers optimal performance, flexible drive options, and robust operation up to 300°C, with multiple materials and surface treatments for enhanced durability.

Read all

RT series

The forward radial-tip blade fan delivers optimal performance across applications, with direct or belt-driven configurations, multiple materials and surface treatments, and robust operation up to 650°C.

Read allCBI stands out for its reliability, custom configurations and full compliance with ISO 9001, ISO 14001, and ATEX standards.

How to determine centrifugal fan rotation direction

Determining the correct rotation direction is straightforward. It is crucial to set the direction according to the fan’s specifications to ensure proper airflow and performance. Here’s how CBI guarantees accurate rotation setup:

-

Design phase alignment - During the engineering phase, the rotation direction is determined based on system layout, airflow path, duct orientation, and required performance specifications. Whether clockwise (CW) or counterclockwise (CCW), the rotation is clearly defined and documented within the technical drawings.

-

Factory configuration - At our production facility, fans are built to match the specified rotation. The impeller and housing are assembled accordingly, and directional indicators (arrows and labels) are applied directly to the fan housing for clarity.

-

On-Site verification - During installation and commissioning, CBI technicians verify rotation direction by performing initial dry runs or visual checks. If powered, they temporarily activate the fan motor to observe the actual movement of the impeller and ensure it corresponds with the designed direction.

-

Custom configuration support - For third parts fans, CBI provides on-site technical assessments, using 3D scanning or diagnostic tools to understand system constraints and configure the fan rotation accordingly—minimising disruption and ensuring compatibility with existing ductwork.

By taking ownership of both the design intent and installation execution, CBI guarantees that every fan operates on its best—maximising airflow, performance, and system efficiency from day one.

Why choose CBI Group for your centrifugal fans?

Choosing CBI means partnering with a full-scope industrial fans expert offering:

- Complete assistance: from installation to predictive maintenance

-

Revamping services for performance recovery and upgrades

-

Aeraulic testing and diagnostics on-site

-

Spare parts supply, including non-CBI fans

CBI ensures every fan is configured with the correct rotation, based on layout constraints, pressure requirements, and system specifications.

Contact us