How Does Centrifugal Fan Design Work?

Centrifugal fan design is at the core of our commitment to innovation. It’s not a standardized process, but a continuous research journey aimed at developing increasingly efficient and safe solutions for our clients. Every new design stems from the drive to optimize the transformation of energy into air movement, while reducing energy consumption and enhancing safety in industrial settings. The goal isn’t just functionality, but achieving excellence in performance.

As a result, it is vital to deeply understand how to customise the fan to make it compliant with specific application requirements.

This article will delve into:

What Are The Stages Of Centrifugal Fan Design?

In order to design a centrifugal fan which is functional, versatile, and mechanically advanced demands to assess many factors. Through a series of well-defined stages, experts can verify that the device presents all the necessary specifications to meet the performance criteria required.

-

It all begins with a preliminary interview between the customer and the engineers to highlight the core features of the centrifugal fan, such as the volume of air, the pressure rate, and the field of application. This phase kickstarts the design process.

-

Based on the elements emerged in the initial analysis, engineers select key parameters to start designing the fan.

-

Once key aerodynamic factors have been evaluated, decisions about blade type, dimensions, rotational speed, and motor power follow. At this stage, the shape, and curvature of the blades play a crucial role in optimizing airflow and minimizing noise, ensuring a balance between performance and efficiency.

-

When it comes to the centrifugal fan structure design, the most relevant element to take into consideration is its integrity. For this reason, materials and components must be meticulously selected to craft a device which is capable of enduring operational stresses under challenging environmental conditions.

-

Once these characteristics are defined, the fan undergoes thorough testing in our test facility, where we evaluate its resistance to vibration, noise levels, performance, and durability. These tests, often conducted in the presence of the client, are essential to ensure that the system complies with national and international safety standards.

-

As a result of the testing feedback, some design fine-tuning changes are made to address any potential issues of the centrifugal fan.

-

Finally, the production cycle is carefully planned and monitored to ensure the fan is manufactured meeting the customer’s deadline, and quality requirements.

.

Would you like to know more about the CBI Group centrifugal fan design process?

Contact us

What Factors Should You Consider When Designing A Centrifugal Fan?

Multiple features need to be evaluated when designing a centrifugal fan. Here are some key considerations.

Application

Based on the context where the fan will be located and the type of industry, specific requirements may arise, such as:

- Volume of air

- Static pressure

- Temperature conditions

These factors are crucial in defining the centrifugal fan’s suitable parameters for specific industrial applications.

Aerodynamic Performance

The selection of the impeller design, the blades’ orientation, and the shape of the fan housing can influence the performance of the system in terms of energy consumption and efficiency.

Noise Levels

The centrifugal fan design process must take into account the noise-sensitivity of certain settings. Integrating sound-dampening materials and designs is crucial to ensure the fan operates efficiently in environments where noise reduction is critical.

Material Selection

The materials’ choice is at the heart of centrifugal fan design, as it contributes to the durability of the device. Furthermore, it impacts the system’s resistance to corrosion, chemical substances, wear and tear.

Accessibility

A fan can be designed to significantly reduce downtime and operational costs. In fact, some centrifugal fans are crafted to allow the personnel access to the ventilation system for regular cleaning. This enables a constant monitoring of the components so that it is easier to replace them when needed, as well as the use of specific tools for predictive maintenance.

Safety Compliance

Another important aspect to consider is the ventilation solution’s compliance to safety standards and regulatory protocols. Whilst designing a fan, explosion-proof designs in hazardous environments are mandatory, and be aligned with the industry guidelines in terms of the operator’s safety and well-being.

CBI Group has a ground-breaking approach to centrifugal fan design to deliver the best possible solution to its customers. The final result is a reliable product, the result of years of research and advanced development techniques that perfectly combine practical engineering insights to cater to the diverse needs of national and international markets.

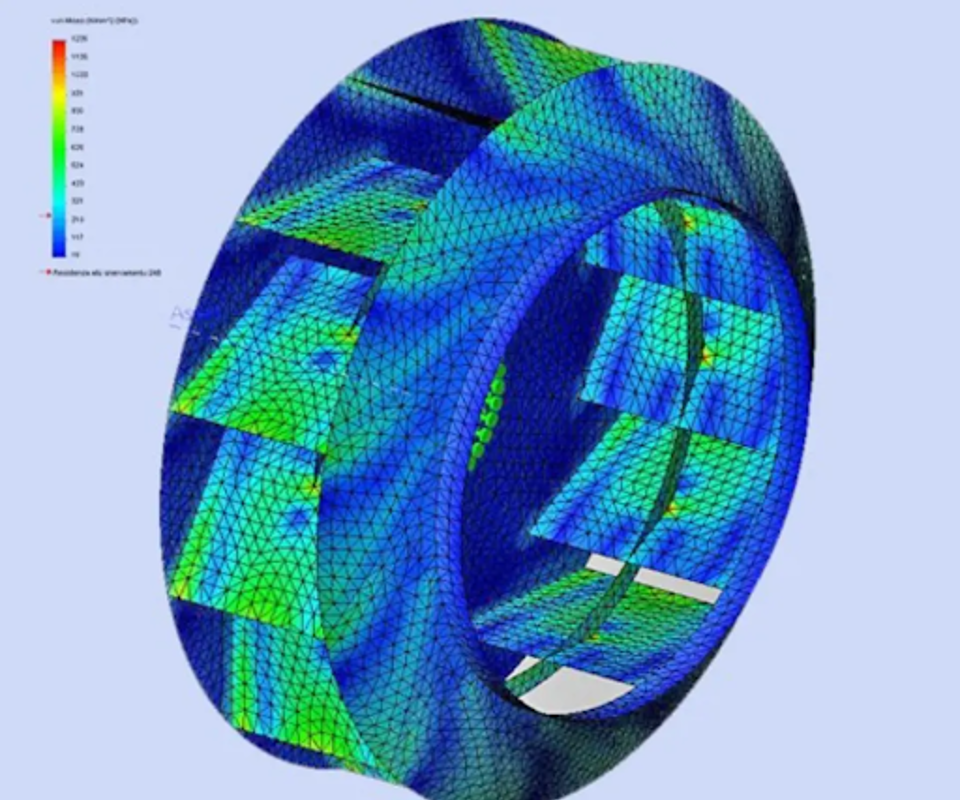

Our mission is to provide sophisticated fans that can effectively operate in multiple contexts. Thanks to computational fluid dynamics (CFD) and finite element method (FEM) analyses, our experts can predict the fans’ performance over time, enabling the optimisation of airflow patterns, and ensuring the robustness of the device even before the prototyping phase.

In particular, the CFD assessment technique is based on simulations that give a detailed report of the fluid dynamics of the fan for further aerodynamic fine-tuning. Conversely, the FEM method is more focused on mechanical aspects, such as the resistance and durability of the components under several operational stresses.

Then, the CBI Group experts build an exact model of the fan that will undergo several tests to assess every aspect related to its performance, including potential issues that could compromise the quality of the output.

CBI is committed to deliver centrifugal fans that are the epitome of excellence. From the design phase to post-sales assistance, our team is engaged in offering you blowers which can deliver unrivalled ventilation quality, tailored to your needs.

Would you like to know more about the CBI Group centrifugal fan design process?

Contact us