Incinerator fans: essential for effective waste disposal

Incinerator fans are essential components in contemporary waste-to-energy and industrial incineration infrastructures. Engineered for precise control of air movement within complex systems, they sustain favorable combustion dynamics, enabling safe operations, full regulatory compliance, and optimized energy recovery.

Discover all products

What is an incinerator fan?

An incinerator fan is a purpose-built industrial fan responsible for supplying the airflow necessary for combustion within the incinerator chamber. Its role is twofold: introducing fresh air into the combustion zone and aiding in the systematic exhaust of emissions through the flue. By regulating air quantity and maintaining thermal balance, the fan achieves complete burning, minimizes residual waste, and prevents the buildup of harmful gases that could compromise safety or ecological standards.

Why are incinerator fans important?

Incinerator fans are vital for the overall reliability and legal conformity of incineration units. They orchestrate air distribution to facilitate complete waste eradication, minimize environmental impact, and maximize energy recovery from the process. Consistent pressure regulation prevents equipment malfunction and mitigates mechanical strain on the structure, supporting seamless operation of waste-based energy conversion facilities under varying conditions.

CBI Group’s incinerator fans: designed for reliability and efficiency

CBI Group offers a comprehensive range of incinerator fans, manufactured for intensive industrial applications.

All major series – S, M, X, Ch – are available in ATEX-certified versions, suitable for explosive environments requiring strict safety measures.

These fans are developed for:

-

Enhanced flow and pressure regulation for uniform combustion throughout the system.

-

Reduced vibration and sound emissions, through precision balancing and refined acoustic design.

-

High durability, with components and materials capable of withstanding extreme temperatures and continuous use. A range of special executions is available, including AISI, gastight, and insulated designs, with options like Polypropylene for specific corrosive and acidic environments.

-

Custom configurations suited to individual plant requirements, leveraging CBI’s expertise in advanced analysis and testing services, such as CFD (Computational Fluid Dynamics) and FEM (Finite Element Method),applicable to both new fan design and existing plant optimization.

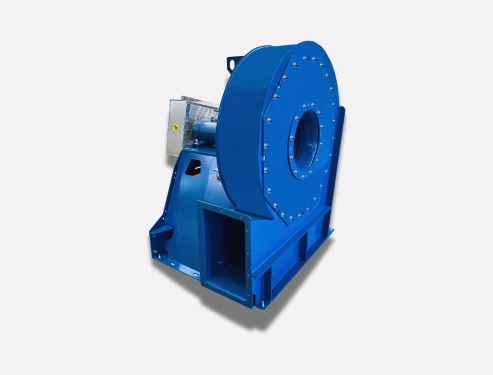

Ch series

Versatility, robustness, and reliability define these fans, making them suitable for a wide range of standard and special industrial applications.

Read all

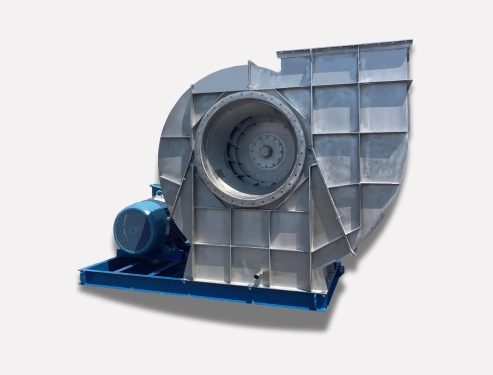

S series

The S/M/X fans are designed for heavy-duty applications, available with direct or belt-driven drives, with 8-blade impellers for the S series, 10 for the M series, and 12 for the X series.

Read all

M series

The S/M/X fans are designed for heavy-duty applications, available with direct or belt-driven drives, with 8-blade impellers for the S series, 10 for the M series, and 12 for the X series.

Read all

X series

The S/M/X fans are designed for heavy-duty applications, available with direct or belt-driven drives, with 8-blade impellers for the S series, 10 for the M series, and 12 for the X series.

Read all

Each fan undergoes rigorous testing in advanced laboratories, including structural and aerodynamic assessments, to guarantee dependable performance under all conditions. This ensures not only the longevity of the equipment but also the safety and efficiency of the entire incineration process.

Why choose CBI Group for your incinerator fan needs?

With more than 60 years of industry experience, CBI combines advanced engineering, innovative research, and international assistance to supply fans that satisfy stringent industrial criteria.

Selecting CBI grants access to:

-

Tailored solutions specifically adaptable to any incineration system.

-

Extensive R&D capabilities, ensuring maximum performance and energy efficiency.

-

Global service and support, including installation, commissioning, maintenance, and revamping of existing plants.

CBI’s incinerator fans remain the preferred option for industrial enterprises seeking resilient, efficient, and ecologically responsible alternatives. By optimizing combustion conditions, lowering pollutant output, and ensuring safe operation, these systems are integral to state-of-the-art waste management and energy recovery facilities worldwide.