- Homepage

- Applications

- Nuclear Fans

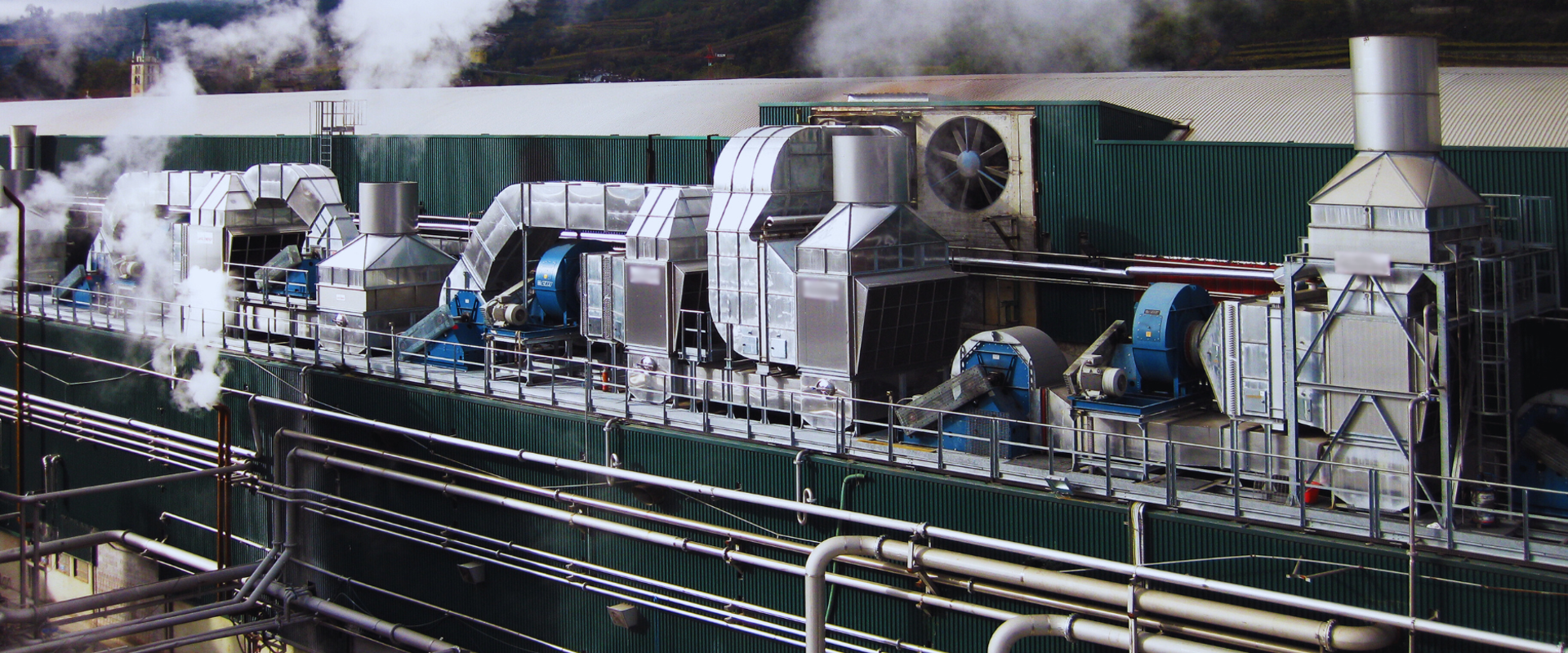

Nuclear Fans

These industrial fans provide essential support across a range of operations, including reactor cooling, plant ventilation, radioactive gas extraction, and nuclear fuel cooling. Each fan is specifically designed to ensure maximum efficiency while adhering to safety standards in complex nuclear environments.

In the past year alone, more than 30 nuclear-grade ventilation systems have been successfully installed, confirming CBI’s continued commitment to technological excellence and operational reliability in one of the most demanding industrial sectors.

Nuclear facilities require ventilation systems that meet strict operational benchmarks. CBI solutions are built to comply with rigorous industry regulations, helping mitigate risks and protect personnel health throughout the plant.

Discover how CBI’s engineering expertise addresses daily maintenance challenges, providing guidance to optimise performance while maintaining precision and compliance. Our team offers technical support, on-site inspections, and structured maintenance planning to keep systems running at peak efficiency.

Contact us for more information!

The new frontiers of nuclear ventilation

In nuclear facilities, fans are not just components; they are key elements that ensure controlled environments, prevent contamination, and guarantee safe operation.

CBI nuclear fans combine mechanical strength, air-tight performance, advanced sealing systems, and long-term durability. Each unit operates reliably under extreme temperatures, pressures, and environmental conditions, providing a stable and secure atmosphere across all areas of the facility. Advanced materials and coatings provide resistance to corrosion, radiation, and thermal stress, while regular quality checks guarantee performance aligned with international standards.

Reactor Cooling

This is a critical process where nuclear fans are actively engaged in maintaining optimal core and auxiliary system temperatures, ensuring the correct functioning of reactors even in the event of an accident. These ventilation systems are designed to handle intense heat loads and preserve a stable and safe operational environment.

Plant Ventilation

In the energy sector, plants never stop working, as they need to provide the right amount of electricity at all times. CBI advanced nuclear ventilation systems and power plant fans are ideal to ensure machine-efficiency, personnel welfare and continuous production reliability. Systems are designed to maintain air quality, temperature control, and vibration minimization, even during 24/7 operation.

Radioactive Gas Extraction

Operators in nuclear facilities deal with hazardous and radioactive gases. CBI nuclear fans are engineered to extract, contain, and safely direct these gases, preventing contamination. Advanced sealing and gas-tight construction ensure safety for personnel and compliance with nuclear ventilation standards.

Nuclear Fuel Cooling

Risk-management is a highly important as nuclear ventilation is at the heart of fuel cooling. CBI fans support the circulation of air, heat removal, and containment of hazardous substances, keeping reactors and fuel storage within safe temperature ranges. Materials and systems are tested for long-term exposure to thermal, chemical, and radiological stress, ensuring consistent performance and accident prevention.

Would you like to know more about CBI nuclear ventilation solutions?

Contact us for further information

Custom Nuclear Fans

CBI provides tailor-made solutions for specific operational requirements. We work with you to define:

- The nuclear facility

- The fan location

- Airflow and pressure rate

- Environmental conditions

- Any other relevant factors

Once these aspects are set, the design process begins. Thanks to our expertise, we will craft your custom nuclear fan according to all defined specifications.

In producing nuclear ventilation systems, we adopt a series of best practices, such as:

- Selecting only the finest and most resistant materials, suitable for high-temperature and high-radiation environments

- Testing every component under extreme operational scenarios

- Checking the performance of the fan in specific plant applications

- Verifying compliance with safety standards, including ISO 9001:2015 and IECEx QAR certification

- Offering technical support, maintenance planning, and on-site inspections for lasting reliability

Certifications and regulatory compliance

CBI Group ensures all nuclear ventilation solutions meet the highest standards of quality. Manufacturing processes are certified to ISO 9001:2015 (Quality Management), ISO 14001:2015 (Environmental Management), and ISO 45001:2018 (Occupational Health and Safety), reflecting our commitment to excellence in production and service.

Would you like to know more about our customised nuclear fan solutions?

Contact us for more information

Divisions

The CBI Divisions specialise in offering specific and customised nuclear fans and services. Learn more about our Divisions.

Heavy Duty

The Heavy Duty Division is focused on robust, high-strength, and intensive fan solutions, designed to tackle the most demanding applications.

Find out more

Industrial

The Industrial Division, thanks to a wide range of standard ventilation products, is focused on providing you with the best solutions for your industrial processes.

Find out more

Engineering

The Engineering Division, through a know-how gained in over 60 years, is able to design and manufacture customised industrial centrifugal and axial fans for any of your needs.

Find out more

Infrastructure

The Infrastructure Division can provide you the most performing ventilation solutions to meet the high standards of the infrastructure sector.

InfrastructureFind out more

Service, Spares & Maintenance

The Service Division is focused on providing qualified assistance services, including:

- Support in the installation of industrial fans

- Start-up activities

- Revamping operations

- Reverse Engineering

- Testing

- Diagnosis activities.

It also guarantees the supply of spare parts for any industrial fan.

Find out more

Research & Development

The Research & Development Division is focused on the constant search for optimised performance, the study of fan evolutions and the industrialisation of new solutions.

Our team of engineers uses the most advanced FEM, CFD technologies and modern testing rooms.

Find out more